ANSA is an advanced multidisciplinary CAE pre-processing tool that provides all the necessary functionality for full-model build up, from CAD data to ready-to-run solver input file, in a single integrated environment.

ANSA is the users’ preference due to its wide range of features and tools that meet their needs. The list of productive and versatile features is long and the alternative tasks and processes to be completed using them are countless.

Environment

All software features are accommodated in an integrated environment, with highly customisable GUI. The software is available for all contemporary popular 64bit architecture operating systems, with multi-core CPU usage. The accelerated graphics, the rapid confirmations and function access, the GUI customisation options, the model browser and lists handling, the filtering and modification operations, and the integrated search engine comprise a user friendly environment that ensures outstanding performance and productivity.

CAD data input & clean up

CAD definitions and model structure data in CATIA V4, CATIA V5, NX, Pro/ENGINEER and JT formats can be converted into ANSA files using the available translators. Moreover, custom interfaces to PDM or SDM systems, powered by scripting, bring product and model structure data into the heart of the software.

CAD geometry can be also read in from neutral file formats (iges, step, vda-fs), manipulated and healed by the proprietary powerful built-in geometry engine. A wide range of geometry healing functions, including those for the generation of neutral fibers, deliver geometry descriptions ready to be meshed.

ANSA data management

ANSA Data Management (ANSA DM) is a centralized data management system, used to collect and store in a structured and hierarchical form all engineering data that are used during the development process of a vehicle simulation model. It assures the effective and efficient data handling throughout projects, by streamlining updated model data to engineering teams, allowing the easy sharing of common data and offering access to library items for the analysis dependent solution settings. The DM Browser, moreover, allows the browsing of the DM Root to identify the available CAD versions, study versions and representations for comparison and model update.

Model Comparison and update

An integrated tool that compares two models in order to identify differences in geometry, attributes, solver-specific definitions, as well as connections. User friendly navigation and identification features are provided while a complete or partial replacement can be performed, updating the model according to user directions.

Process Automation

Task Manager and scripting language provide a unique modeling solution for automated and effective applications.

Task Manager is an integrated workflow manager that includes all individual tasks of a simulation model development. The process template is built up by the CAE expert who sets the boundaries between distinct modeling actions and predetermines all modeling parameters that must be respected, leaving to the inexperienced user a minimum degree of interference and limited decision making.

The scripting language is an enhanced programming tool that boosts productivity providing the power to access data and perform custom operations in an automated way.

Meshing

The integrated Batch Meshing tool leads to controllable and effortless optimal results, for both shell and volume meshing. Following the versatile mesh area idealization, geometry can be meshed according to modeling requirements by cutting edge surface and volume meshing and wrapping algorithms.

A unique mesh generation environment is composed by:

- proprietary shell meshing algorithms

- high performance and quality volume meshing algorithms

- state-of-the-art boundary layers elements deployment

- Hexahedral dominant meshing

- Acoustic Cavity mesher and the straight forward Wrapping tool

- one-step mesh generation on automatically extracted middle surface

- numerous mesh handling functions.

Assembly

Powered with fully comprehensive parts and welding management tools, accommodates parts assembly, with alternative node-dependent or independent connections types, appropriate to various disciplines. Interfaces to numerous connections data file formats allow the completion of a single stage assembly. New concepts introduced, including model hierarchy input, multiple part instances handling, parts comparison-replacement and update as well as special joining type creation.

Includes configurator

Different model variants or load cases can be compiled with available include files through one of ANSA’s special tools. This enables the creation of particular model configuration even without loading the respective data.

Pre-processing decks

Pre-processing completion is achieved through the uniquely interoperable pre-processing decks for NASTRAN, LS-DYNA, PAMCRASH, RADIOSS, Abaqus/Standard, Abaqus/Explicit, PERMAS and ANSYS Structural, allowing direct model modification between solvers, including material synchronization. Numerous unique utilities facilitate laborious tasks such as the management of Includes Files, model sub-structuring, entity numbering control etc. ANSA is multidisciplinary by design, in order to simultaneously handle models for Crash, Durability, NVH analysis etc., supporting all entities required by the latest versions of solvers.

A compilation of CFD oriented features are accommodated into special CFD pre-processing decks that support the most popular codes, such as STAR-CD, CCM+, Fluent, OpenFOAM etc.

Analysis tools

Crash and safety modeling is assisted by user friendly features for impactors positioning, seatbelt fastening, positioning and articulation of crash test dummies and "headform" models for passenger and pedestrian safety simulation standard scenarios.

The fast and easy Kinematics tool solves sophisticated positioning problems, for seats, convertible roofs and other mechanisms.

The Laminate Tool is one more enhanced function that assists the modeling of complex parts made of composite materials.

Results Mapping tool enables importing of data regarding nodal thickness, pressure distribution, stresses and plastic strain, nodal temperature, material orientation, etc. that can be mapped from an existing file to a different mesh. The tool ensures the accuracy in the mapping process and handles all major results.

Model integrity checks

Replicates the integrity and correctness checks performed by the solvers, reports potential modeling flaws and proceeds to model auto-correction actions.

Solution control

The above, along with the user-friendly solution scenario definition leads to the output of a ready to solve model. Apart from the formats of the solvers for which complete preprocessing decks exist, i.e. NASTRAN, LS-DYNA, PAM-CRASH, RADIOSS, PERMAS, Abaqus/Standard, Abaqus/Explicit and ANSYS, numerous other file formats are supported, for structural, CFD as well as other solvers.

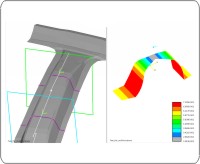

Morphing

One of the most advanced tools developed to meet the needs for fast model modifications is the Morphing Tool. It expands the reusability of existing models by allowing the versatile procession of alternative variations. Morphing operations are performed on FE or geometry models. Applications include fields like optimisation processes and sensitivity analysis.

Tools

The core preprocessing functionality is enhanced with a substantial number of other advanced tools that allow the user to complete specialized tasks without having to leave the software environment. Those tools are the Cross Section Analysis Tool, the Volume Traps Tool and the Fuel Tank Analysis Tool.

Optimization

Numerous software features, including the Morphing Tool, the scripting and the process automation, can be combined to offer versatile coupling with optimizations codes.

Benefits

- Efficient data handling for intricate model structures.

- Fast and high quality modeling of complex geometries.

- Capability to interoperate between models built for different solvers.

- Highly automated processes and model set-up tools in one environment.

- Reduced user-dependent error-prone operations.

- Complete model build-up for numerous solvers in one environment.

- Unique capability for building a common model as a basis for modeling for different disciplines.

- Significant modeling time reduction and quality increase.

- Short learning path and deployment time.