In today's rapidly evolving engineering landscape, effective management of simulation processes and associated data is paramount for ensuring product quality, reducing time-to-market and enhancing competitiveness. Responding to contemporary needs, BETA CAE brings to market SPDRM, the Simulation Process Data and Resources Manager for end-to-end data, process and resources management for CAE.

Simulation Data Management

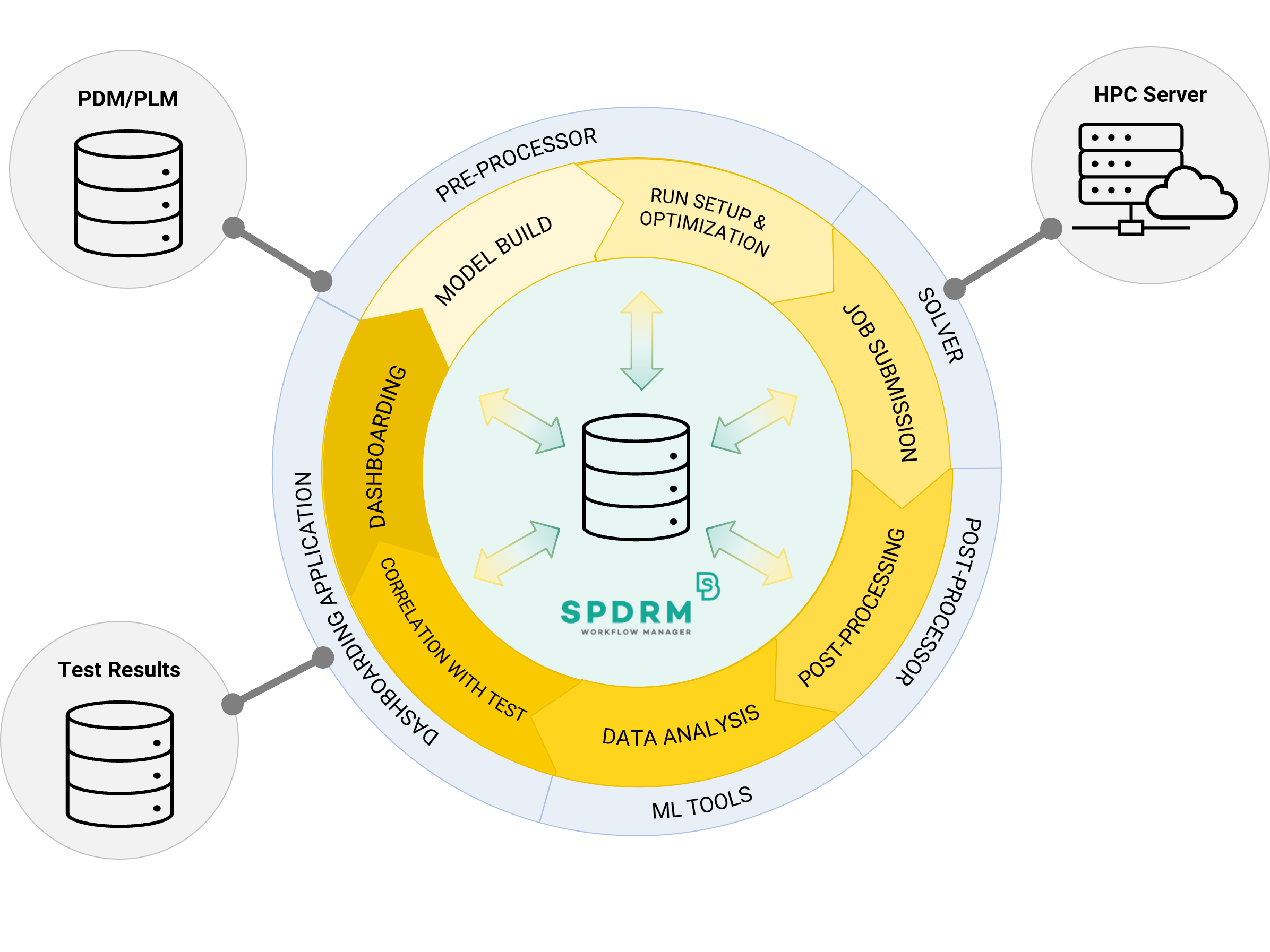

SPDRM offers a systematic approach for data storage that enables all simulation stakeholders to find the right data easily, identify their dependencies and browse their pedigree. With SPDRM, model build and simulation engineers benefit from a common data share point that facilitates collaboration and data reuse and ensures that both internal and external users of the system get access to the right data promptly and hassle-free.

From CAD files and library data to CAE models, simulation data, results and reports, SPDRM has inbuilt knowledge of data relationships and offers all the right tools for attributes handling, version control, lifecycle management and data access control.

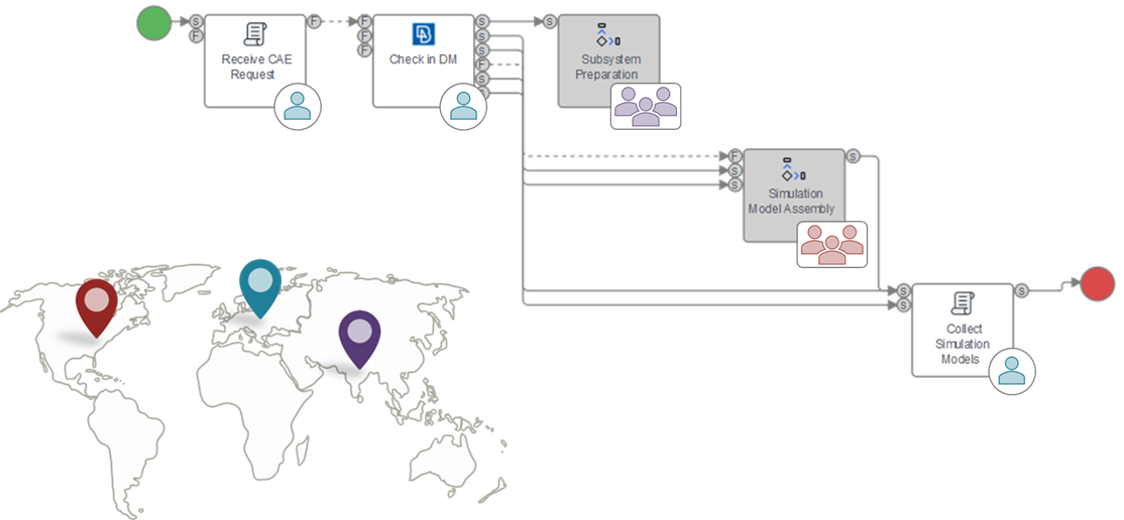

Responding to the needs of different organizations, SPDRM supports both on-premises and cloud data storage. For geographically dispersed engineering teams, SPDRM’s multi-site architecture enables data sharing between remote teams with its optimized remote data synchronization engine that ensures information is available to every user in real time.

Simulation Process Management

In the CAE community, the term Process Management is often used to refer to the standardization and automation of CAE workflows. Usually, more focus is placed on the pre- and pro-processing workflows and their automation through scripts, session files and task management tools. But do these cover all the needs of contemporary engineering teams?

SPDRM takes process management to the next level with its state-of-the-art process management module that enables standardization and automation of cross-application, cross-system and cross-team workflows. CAE process owners can capture even the most demanding processes in the Process Designer as Process Templates that hold information about the applications to be used, the flow of data from one step of the process to the next and the right teams or individuals or even network resources to carry out each process step.

From nightly translation of CAD updates to meshing management and job submission to the HPC, SPDRM’s Process Manager is the enabler for the industrialization, standardization and automation of CAE processes, making it easier to onboard analysts and make effective use of available resources.

Resources Management

SPDRM offers the right administrative tools for the definition and handling of human and non-human resources and a dedicated web portal for their management and monitoring.

User management is role-based, making it possible for the same user to have different privileges when logging into the system with different roles. Privileges can restrict access to data, processes and tools, making it possible for system administrators to create different system set-ups for different user groups.

Applications management is done centrally, so that the right version and configuration of each software is automatically made available to the end users. Furthermore, the embedded task scheduler and workload manager enable the handling of recurring tasks and their delegation to remote resources, always keeping the load of the end-user’s workstation to a minimum.

Interfaces with other systems

SPDRM comes with built-in interfaces to PDM/PLM and CAD systems, that facilitate the import of product structures and their further manipulation before pre-processing. Additionally, it includes pre-configured interfaces to the most established workload management systems (LSF, SLURM, etc.), facilitating the set-up of job submission to the HPC.

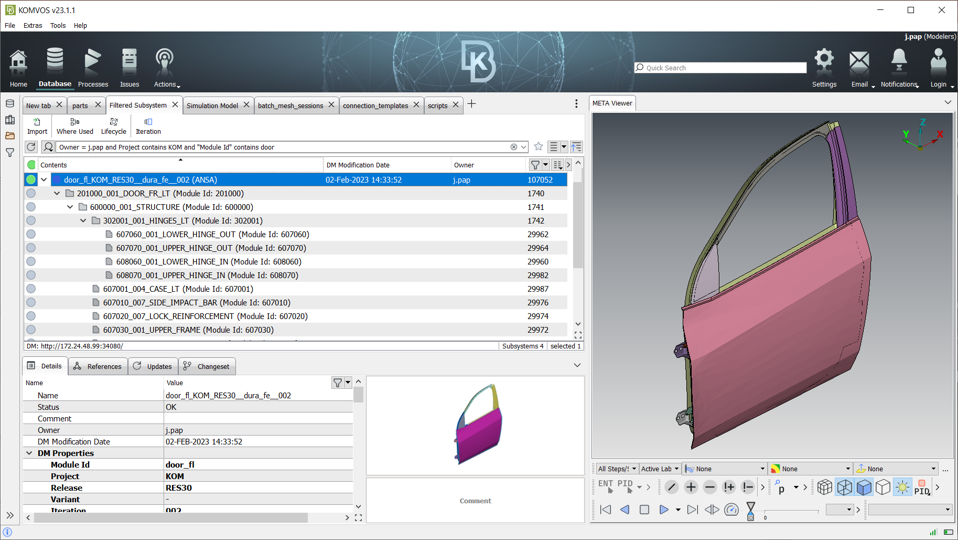

A distinctive feature of SPDRM is its tight integration with ANSA and META, that enable the most advanced pre- and post-processor to make use of its data and process management capabilities through their standard tools and their Python API. Through this integration, model build and simulation engineers can browse through SPDRM data straight from within their ANSA and META sessions, download models to work on and save back as newer versions, submit simulations to the HPC, compare their models and results with other users’ data and get informed decisions without leaving their main workspace.

Graphical User Interface

SPDRM’s Data and Process Management capabilities are made available through its primary client, KOMVOS. KOMVOS is a standalone, desktop application that serves as a rich client of Simulation Process and Data Management systems. With KOMVOS, users can check in and out data, search for data, review product structures, preview models in the embedded 3D viewer, send data to external applications, export data, review processed results, design and execute processes, get notifications on completed HPC jobs, and many more.

All data management functionality of SPDRM is directly available in ANSA and META too, through their inbuilt DM Browser. This tool is built on the same GUI framework with KOMVOS and is based upon the same user interface principles, making it extremely easy for a user familiar with one, to get immediately productive with the other.

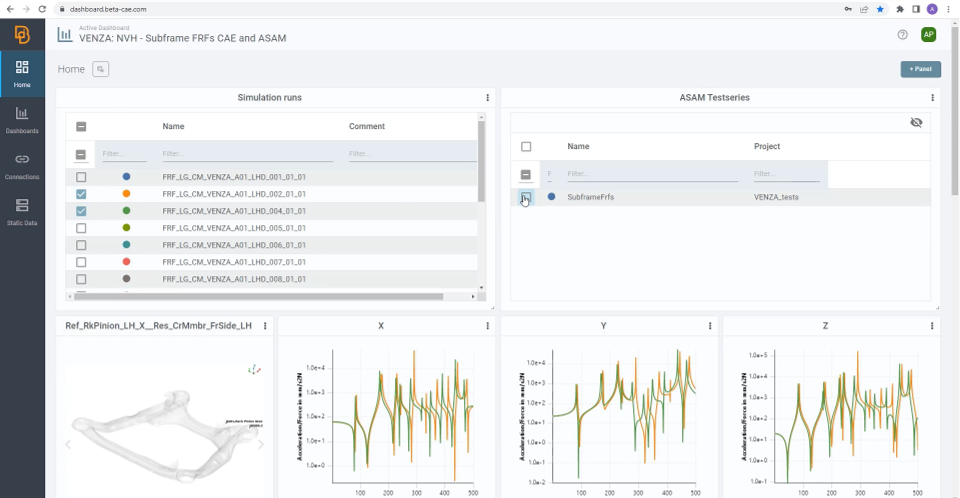

For those cases where access through the web browser is preferred, SPDRM’s Data and Process Management capabilities are also accessible through ANSERS. ANSERS is a web application that offers a dashboard interface for browsing, visualizing and comparing model, simulation and test data. ANSERS enables the definition of different dashboards for different teams and applications, delivering a user interface tailored to the needs of each individual.

Artificial Intelligence and Machine Learning

SPDRM’s Data, Process and Resources Management capabilities are key enablers for the use of Artificial Intelligence and Machine Learning in daily CAE use-cases. With the built-in integration of the ML Toolkit in KOMVOS, data analysis tasks can be easily initiated to generate data insights and ML trained models can be effortlessly created to make predictions and drive research and innovation initiatives.

Benefits

- Enhanced collaboration and reduced data redundancy through centralized data storage.

- Data traceability through the complete digital thread, for simulation verification and troubleshooting.

- Productivity increase with efficient information management and data analytics.

- Quality improvement with standardization of validation procedures.

- Knowledge Management by capturing specialist expertise.

- Performance improvement with the standardization and automation of repeated tasks.

- Seamless integration with other systems (PDM/PLM, HPC, test data management systems, etc.).

- Out-of-the-box integration with Data Analysis and Machine Learning tools.

- Centralized, role-based management of scripts and settings for all BETA Suite applications.

- Scalability with horizontal and vertical scaling, to handle increasing amounts of data and users.